Mike Birdsall, Senior Software Developer, Soft Options

Matt Frederick, Orthotic Service Manager, Sherwood Forest Hospitals

Mike on site during go-live sets up line order processes and Matt working at his new BEST system

Sherwood Forest Orthotics is based in the colourful, modern Kings Mill Hospital located on the outskirts of Mansfield. On the ground floor they have their own department consisting of a dedicated waiting area, reception, store room and packaging area and various clinic rooms. And in the basement, there are the workshops where the service manufactures their own range of equipment and devices, and also undertakes adaptations and repairs.

Kings Mill Hospital, Mansfield

Orthotics services assess their patient’s needs and then prescribe a bewildering array of equipment – insoles, specialist footwear, leg and knee braces, foot/ankle supports to name but a few – aimed at addressing those needs. This is an extremely busy service, featuring 4 Orthotists, 4 Orthotic Technicians, 4 Administrative staff and a technical instructor, catering to some 2300 patients each year, carrying out about 40 appointments a day and issuing over 500 pieces of equipment per month (source: converted data).

Sherwood Forest Orthotics – Processing goods and Reception/Administration

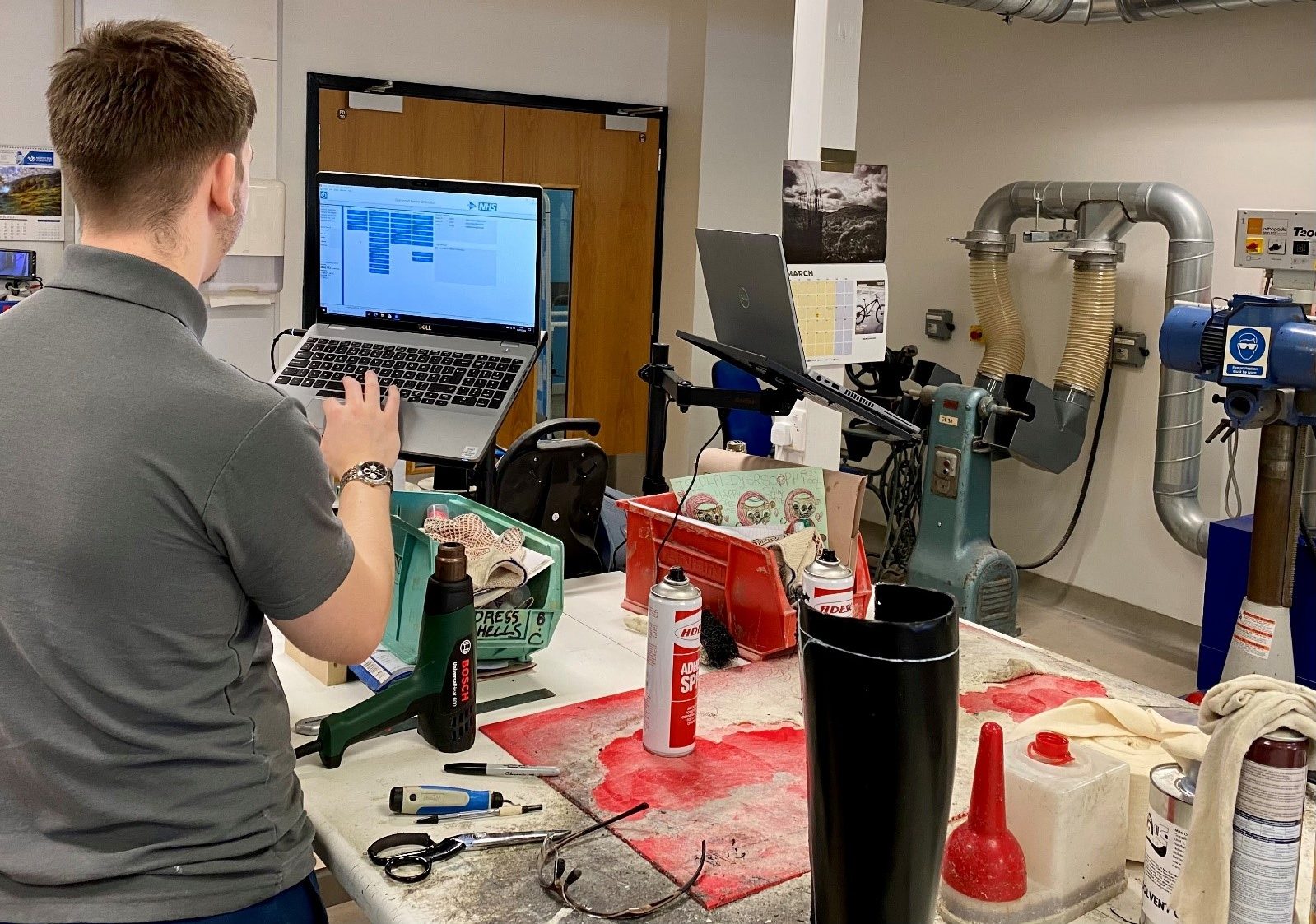

AFOs in the Orthotics workshop

Matt says:

“The service has been an in-house centre for over 25 years providing in-patient and out-patient activity over 4 sites in North Nottinghamshire. We have been keen to move from our current system for the past 3 years due to a variety of issues including data quality, integration and outdated processes.”

Matt tells me that he remembered a presentation given some time ago to the National Orthotics Managers Group (NOMaG) while he was chair by our then MD, Kevin Clegg. So early in 2021 he contacted Soft Options for a demo and, on March 6th, we received the order to supply the new BEST system. For various reasons beyond both parties’ control work on the project didn’t get fully underway for several months.

Mike was chosen to lead the project due to his previous experience, both working in the Cardiff and Vale Orthotics Service and developing software for other orthotics services. He was reassured to know that he would have the support and backing of the full Soft Options team behind him; Simon with the infrastructure and initial setup, Liz for reports, letters and outputs, Dave on Data Conversions and Integration, Kelly and Trevor for front- and back-end developments and Becky on testing – and not forgetting Charlotte with vital Admin and Project Oversight support. His first visit to site was in January 2022 which was a fact-finding mission aimed at getting a feel for some of the special challenges faced by a busy orthotics service.

One of our first challenges, as Matt says below, was getting good quality data out of their existing system. In particular, the existing system had a unique method of storing attached documents and images within the data (BEST saves these as linked files). At first it was thought to be impossible to extract these, but with a considerable amount of ingenuity from the Soft Options development team, this has been achieved.

“The process to deploy BEST has not been straight forward. It has been difficult to extract clinical history and convert. It has also been very problematic to test the system fully before going live as we have carried forward historic data that’s incomplete. Development has also had to continue once live due to converted data anomalies and the wide-ranging Interventions/processes Orthotic Services provide. I personally expected it as we are a busy department that has worked with an out of date and unsupported system for years.”

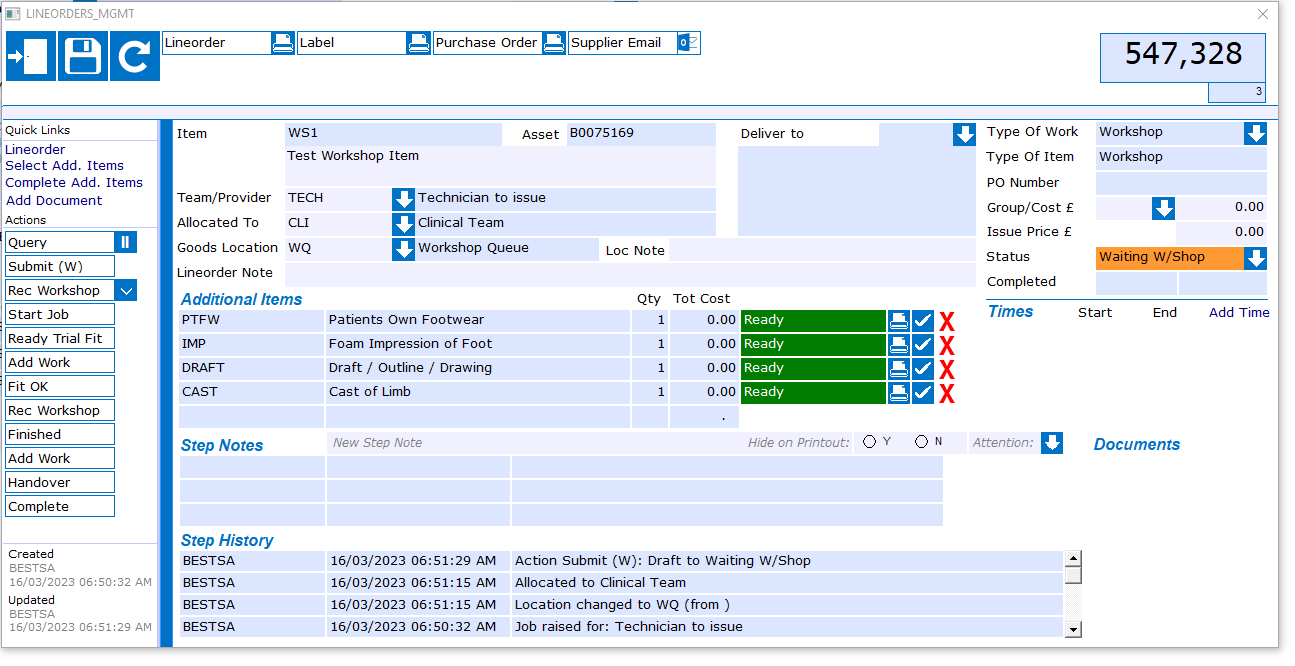

A major difference between orthotics services and other types of equipment services catered for by BEST is the high level of process-based work, both within the in-house workshops and when buying in equipment from external suppliers. There is often a need to pass equipment backward and forward between workshop/external supplier and the Orthotist working with the patient, from raising the original equipment request, manufacturing the bespoke equipment, returning to clinic to trial fit, returning to workshop/supplier for finishing or revision work and final issue to the patient.

Thus, Lineorder Management was born. Developed by Mike, this allows for almost any process to be pre-defined as a series of configurable options. It allows the process to be taken through a series of logical steps, prompting for changes of Team/Provider, Allocation and Location, inclusion of linked Additional Items and Components, step notes and a complete history. It even features the ability to create a “pseudo” purchase order for communication with an external supplier prior to conversion to a “real” purchase order on completion of the work. Extremely flexible, this development will have multiple uses across a full range of equipment services that use BEST.

BEST Lineorder Management screen

“BEST delivers a range of improvements for our service. The system ensures we comply with Trust data quality and reporting requirements while still remaining relevant for an equipment centred service. Episodes of care combine clinical activity along with ordering of equipment. This not only improves our understanding of patient level costs, it ensures patient clinical history revolves around the equipment they have been supplied with.”

Another challenge for high-turnover Services is quick access to accurate, up-to-date patient demographic data. To address this, Dave Rolph Soft Options MD working with Trust IT has developed a link between BEST and the hospital Careflow PAS System. This allows the BEST user, with a couple of clicks, to pull the patient demographics into BEST, including GP details, thus saving valuable time and ensuring reliable data. The PAS Link can even keep the Service up to date with those patients who have unfortunately passed away.

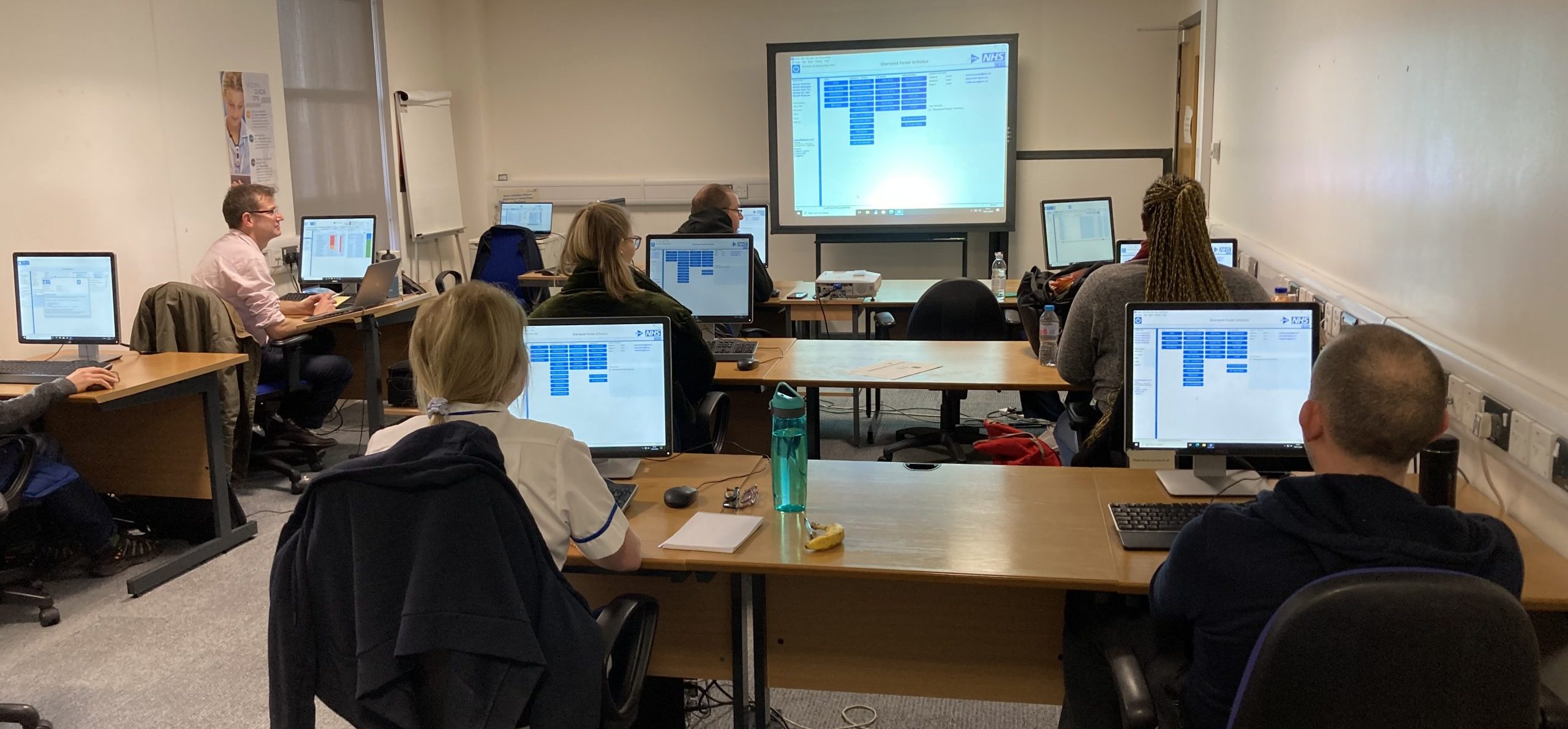

In January 2023, Mike spent 4 days on site delivering BEST Training to all staff. This was carried out in one of Sherwood Forest Hospitals NHS Trust’s dedicated training rooms, which was well kitted out with projector, screen and computer for the trainer, and sufficient other PCs that for most sessions there was enough for one each so that the staff could follow the lesson, trying out the functions for themselves.

Orthotic Technician at work

“Knowing that it was going to be a difficult transition for the service, it has been a relief to work with a company like Soft Options. It has been a stress time where the department has to remain open but staff learn new processes and become familiar with the system. Orthotic services offer a large range of interventions, in different settings in a variety of ways. Working with the team at Soft Options we have ensured these variations are catered for. This makes our system feel bespoke for our needs.”

Following a trial go live on February 14th, the new BEST Orthotics system for Sherwood Forest went live on February 27th. Mike was again on site with the aim of making this process as smooth as possible. Between then and now (21/03/2023) Soft Options have continued to work with Matt and his Team to support them through the transition, particularly while the data from the old system works its way through to completion. Soft options have continued to learn from the experience of working with Sherwood Forest Orthotics and already have further developments for them in the pipeline – all of which will be available for future BEST customers and will benefit orthotics and the full range of equipment services alike.

Mike delivers BEST training